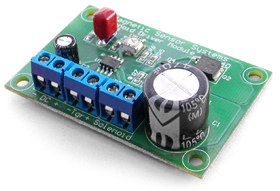

Solenoid Driver Module

Pick and Hold Module SDM840

| One method of consuming less energy is to

apply a voltage to the solenoid coil to provide the necessary force to

pull the plunger in, then, when seated, drop the voltage down to a level

sufficient to maintain the plunger in a seated position. (See example in

Minimizing Unnecessary Energy Consumption

;

Voltage Reduction.)

MSS' Pick and Hold Module is designed to apply an initial higher voltage to the coil for a pre-determined period of time and then drop the voltage to a pre-determined percentage of the initial value through pulse width modulation to avoid over heating the solenoid coil. The above voltage sequence will be applied to the coil when a voltage (2 to 40 VDC) is applied to the trigger. The trigger voltage can be a secondary voltage (external trigger) or the same voltage used for input voltage (internal trigger). This is particularly useful when a solenoid requiring a relatively large amount of power needs to be turned on and off with a low power trigger voltage such as a TTL compatible signal. |

|

| Parameter | Min | Typical | Max | Units |

| Supply Voltage | 8 | 40 | VDC | |

| Peak Current (During Pick Time) | 20 | A | ||

| RMS Current | 3 | A | ||

| Command (Trigger) Range | 2 | 40 | VDC | |

| Command Input Resistance | 50 | KOhms | ||

| Operating Temperature | 0 | 80 | Deg C | |

| Storage Temperature | -40 | 125 | Deg C | |

| PWM Frequency | 20 | KHz | ||

| Pick Time | 100* | mSec | ||

| Holding Voltage to Supply Voltage Ratio | 30** | % |

* Pick time can be made longer in factory on special orders. 100, 250 and 1000 millisecond pick times are readily available.

** Holding voltage is preset in factory at 30% of input voltage. This value can be adjusted with the potentiometer on the board.

Copyright © Magnetic Sensor Systems

Rev. 01-01-05